Industry Knowledge

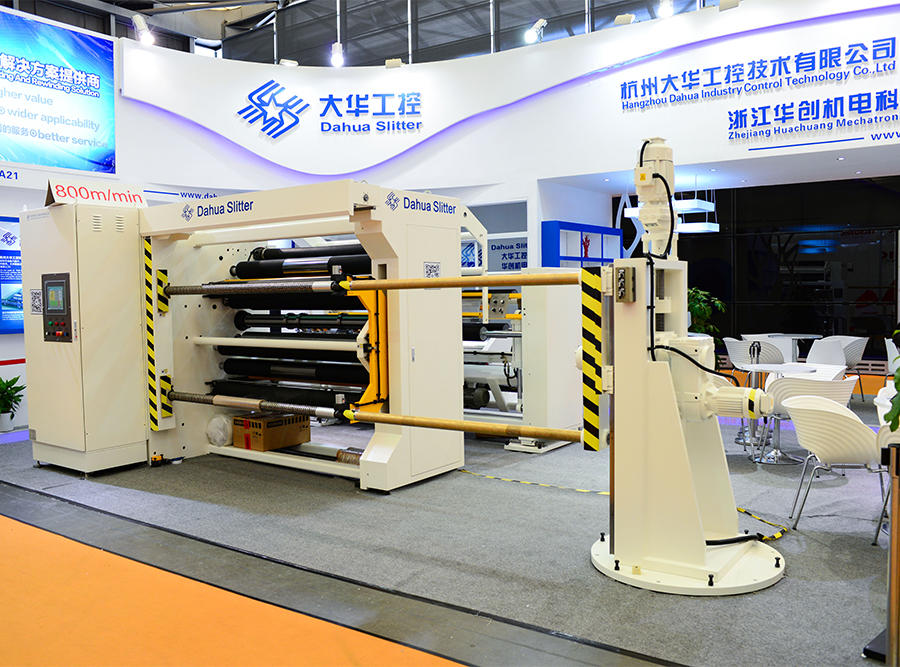

The Importance of Shaft Type Slitter

A shaft type slitter is an important tool used in many industries for the precise cutting of a wide range of materials into narrower strips or rolls. Here are some reasons why a shaft type slitter is important:

Precision cutting: Shaft type slitters are capable of precise and consistent cutting of materials, which is essential for achieving high-quality finished products. They can achieve very narrow cut widths, which is important in many applications, such as in the production of electronic components.

Versatility: Shaft type slitters can be used to cut a wide range of materials, including metal, plastic, paper, and textiles. This versatility makes them a valuable tool in many industries.

Speed and efficiency: Shaft type slitters can operate at high speeds, which increases production output and efficiency. They can also be configured to handle larger roll sizes, reducing the need for frequent roll changes.

Customization: Shaft type slitters can be customized to suit specific production requirements. For example, they can be configured with different blade types, widths, and thicknesses to achieve different cut patterns.

Cost-effective: Shaft type slitters are a cost-effective solution for cutting a wide range of materials. They are relatively inexpensive compared to other cutting methods and can provide a good return on investment over time.

Overall, a shaft type slitter is an important tool in many manufacturing and production industries, enabling precise and efficient cutting of a wide range of materials to meet specific requirements for various products. They are essential for achieving high-quality finished products, increasing production output, and reducing waste in the production process.

The working principle of Shaft Type Slitter

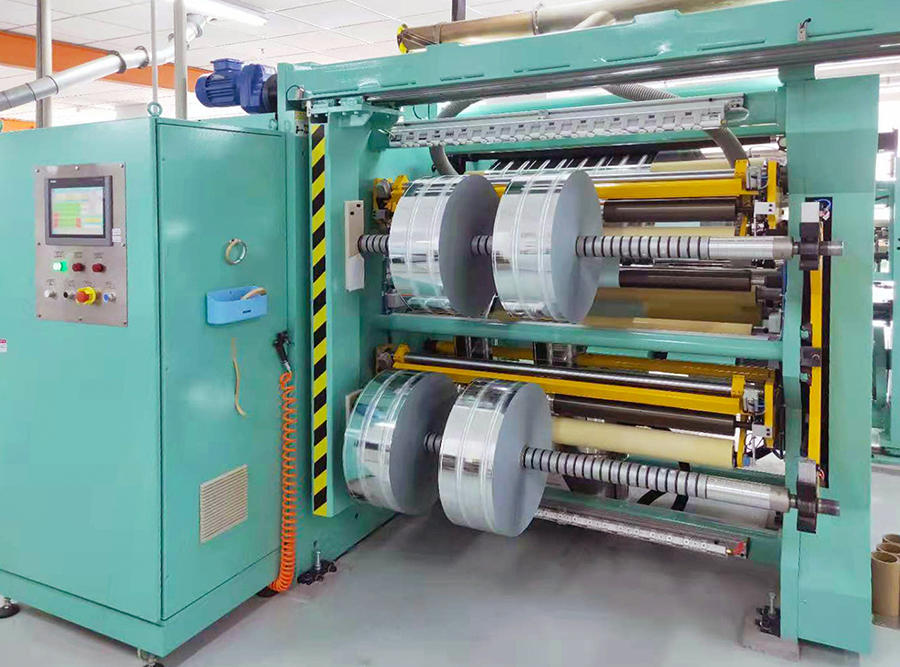

The working principle of a shaft type slitter involves the use of a set of blades or knives that cut through a material as it passes through the machine. Here are the basic steps involved in the working principle of a shaft type slitter:

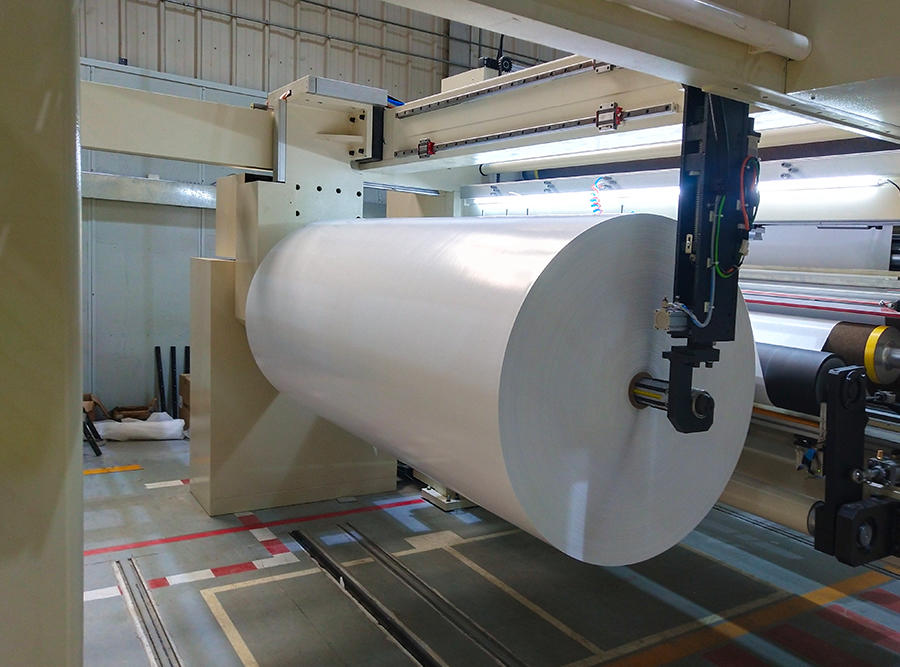

Material unwinding: The material to be cut is unwound from a roll and passed through the slitter machine.

Material alignment: The material is guided through the machine to ensure that it is properly aligned for cutting.

Slitting: The material is passed between a set of rotating blades that cut it into narrower strips or rolls. The blades can be adjusted to achieve different cut widths.

Rewinding: The cut material is rewound onto individual shafts or cores, ready for further processing or use.

The above steps are the basic principles involved in the working of a shaft type slitter machine. However, there are several variations in the design and operation of the machine that may depend on the type of material being cut, the required cut width, and the production volume.

Shaft type slitters can have different numbers of shafts, which can be customized based on the specific production requirements. The blades can also be arranged in different configurations, such as shear or crush cut, depending on the type of material being cut.

Overall, the working principle of a shaft type slitter is relatively straightforward and involves the use of precision blades to achieve precise and consistent cutting of a wide range of materials.

EN

EN

English

English Español

Español 中文简体

中文简体

.jpg?imageView2/2/format/jp2)