Industry Knowledge

How to Install Secondary Station Type Slitter?

Installing a secondary station type slitter involves several steps to ensure that the machine is installed safely, properly, and according to the manufacturer's guidelines. Here are some general steps for installing a secondary station type slitter:

Prepare the site: Clear the installation area and ensure that it is level and free from any obstructions or hazards. The site should have sufficient space for the machine, as well as any required electrical and ventilation systems.

Assemble the machine: Follow the manufacturer's instructions to assemble the slitter machine, including installing the blades, rollers, and other components.

Connect the electrical and ventilation systems: Install any necessary electrical wiring, control systems, and ventilation systems according to the manufacturer's instructions and local building codes. Ensure that the machine is properly grounded and that all electrical connections are secure.

Test the machine: Before operating the machine, perform a test run to ensure that all components are properly installed and functioning as intended. Check for any unusual sounds, vibrations, or other issues that may indicate a problem.

Train the operators: Provide adequate training for the machine operators to ensure that they are familiar with the machine's operation, safety features, and maintenance requirements.

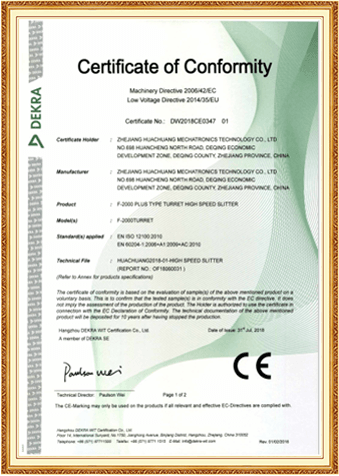

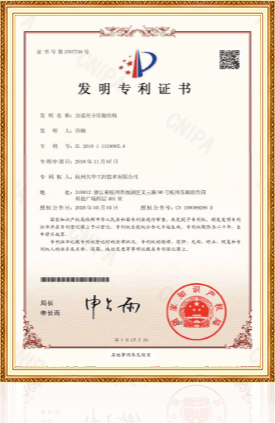

Ensure compliance with regulations: Check that the machine and its installation comply with all relevant regulations and standards, including safety, environmental, and industrial requirements.

Maintain the machine: Develop a maintenance schedule and perform regular checks and maintenance on the machine to ensure its continued safe and efficient operation.

Overall, installing a secondary station type slitter involves careful preparation, assembly, testing, training, and maintenance to ensure that the machine is installed safely, operates efficiently, and meets the production requirements of the facility. It is essential to follow the manufacturer's guidelines and any relevant regulations or standards to ensure the proper installation and operation of the machine.

The Advantages of Secondary Station Type Slitter

A secondary station type slitter offers several advantages over other types of slitter machines, making it a popular choice for many manufacturing and production industries. Here are some of the advantages of a secondary station type slitter:

High precision cutting: Secondary station type slitters can achieve high precision cutting of materials, with accurate and consistent cut widths, even at high speeds. This allows for greater quality control and reduces waste in the production process.

Flexibility: Secondary station type slitters can be used to cut a wide range of materials, including metals, plastics, textiles, paper, and more. They can also be configured to cut multiple widths, making them highly versatile and adaptable to different production requirements.

Increased productivity: Secondary station type slitters can operate at high speeds, increasing production output and efficiency. They can also be configured to handle larger roll sizes, reducing the need for frequent roll changes.

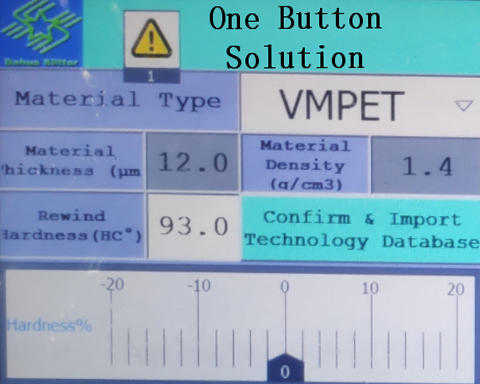

Reduced setup time: Secondary station type slitters can be equipped with automatic setup features, reducing the time and effort required to change blades and configure the machine for different materials or cut widths.

Improved safety: Secondary station type slitters are designed with safety features such as guards, emergency stop buttons, and interlocks to protect operators from hazards during operation.

Cost-effective: While the initial investment in a secondary station type slitter may be higher than other types of slitter machines, the increased productivity and efficiency can provide a good return on investment over time.

Overall, a secondary station type slitter offers several advantages, including high precision cutting, flexibility, increased productivity, reduced setup time, improved safety, and cost-effectiveness. These benefits make it a popular choice for many manufacturing and production industries.

EN

EN

English

English Español

Español 中文简体

中文简体

1-1.jpg?imageView2/2/format/jp2)

2.jpg?imageView2/2/format/jp2)

3.jpg?imageView2/2/format/jp2)

4.jpg?imageView2/2/format/jp2)