How much do you know about medicinal PVC blister film?Chinese pharmaceutical packaging has gone through three stages. The first stage is the 1950s, such as brown glass bottles, straw cartons and other drug packaging. The second stage is the adjustment stage in the early 1970s and 1980s. The third stage is the 20th century. Since the 1980s, packaging suitable for dosage forms such as oral liquids, capsules, and capsules has been developed. Among them, aluminum-plastic blister packaging is developing rapidly.

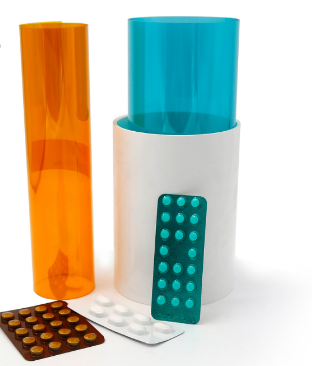

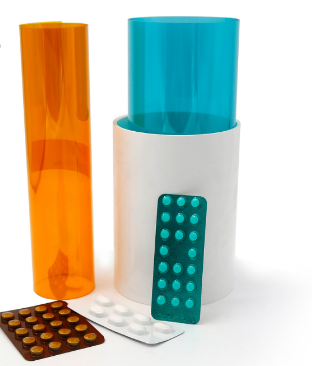

Aluminum plastic blister packaging is also known as Blister eye packaging (PTP) packaging for short. PTP packaging is to first transport the plastic sheet to the electric heater to soften it, then place the sheet in the mold, fill the sheet with compressed air from the upper mold or vacuum the lower mold, so that the sheet forms a blister. After the material is formed and cooled, the drug is put into the blister, and the side of the medicinal aluminum foil coated with the adhesive is heat-sealed with the plastic sheet containing the drug under certain temperature, pressure, and time conditions to form a Blister packaging. PTP packaging materials include medicinal aluminum foil, plastic hard sheet, etc.

The most common plastic hard film is PVC blister film. In recent years, although PP, PET and other PTP aluminum-plastic packaging surface materials have also developed, and have advantages over PVC in some aspects of performance, they are far inferior to PVC in terms of processing performance and production efficiency, and the production of these types Due to the high cost and narrow scope of use of hard tablet equipment, it can only be used for a small amount of special medicines. PVC blister film is still the most important PTP packaging material.

PVC blister film can be produced by extrusion and calendering, and its main raw materials are PVC resin, plasticizer, heat stabilizer, processing aid, lubricant, etc. Because of health and safety considerations, the selection of raw materials and formulas is very particular. In fact, PVC blister film contains about 90% PVC resin, and other additives only account for a small part. Specific conditions: PVC resin: 88-92%, plasticizer: 0-1%, heat stabilizer: 1-1.5%, lubricant: 1.5-2% and some other processing aids. The selection of raw materials in all formulas must meet the requirements of medicinal use. Therefore, before pharmaceutical companies decide to use PVC blister film provided by packaging material manufacturers, they must conduct stability tests and compatibility tests. Once the use is confirmed, the raw material formula of the PVC blister film cannot be changed.

Dahua Industry Control Technology Co., Ltd. offer

Medicine Packaging PVC Blister film Slitting Machine