Basics of MLCC that you must know1. What are MLCC?MLCC is the English abbreviation of Multi-layer ceramic capacitors. It is one of the most widely used and fastest-growing basic components in the world. It is called "rice in the electronic industry".

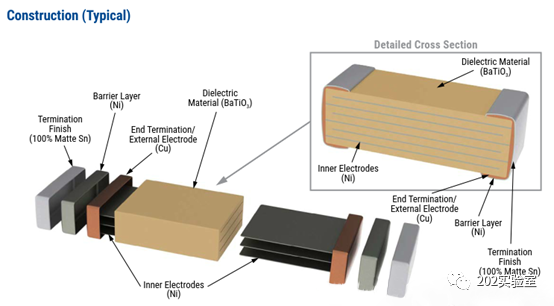

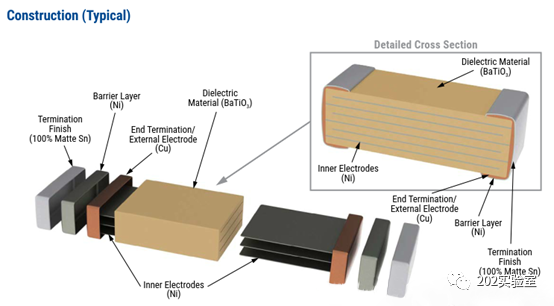

2. The basic structure of MLCC:

From a structural point of view, MLCC is composed of layers of internal electrodes and insulating dielectric materials distributed between the electrodes in a dislocation manner, and is sintered at a high temperature to form a ceramic chip, and then made at both ends of the capacitor. The electrodes available for welding, MLCC can be regarded as a more advanced parallel plate capacitor, and its final structure is equivalent to the parallel connection of many parallel plate capacitors.

3. Development history of MLCC industry From 1900 to 1960, with the Italian scientist L. Lombardi inventing the ceramic dielectric capacitor in 1900 as a signal, the MLCC industry entered the embryonic stage. Because ceramic capacitors can work in a very wide temperature range, ceramic capacitors were initially used in military electronic equipment that required both small size and high precision.

From 1960 to 1990, marked by the successful development of multi-layer ceramic capacitors (Multi-layer ceramic capacitors) by an American company in the 1960s, it opened the development stage of the MLCC industry, and later it was rapidly developed by Japanese manufacturers and industrialized.

Since 1990, it has been a stage of rapid development of the MLCC industry. During this period, the MLCC industry set off a technological revolution. Since the inner electrode palladium is a precious metal, in order to reduce costs, through the development of materials, equipment, and manufacturing processes, the nickel inner electrode has successfully replaced the palladium inner electrode and silver palladium. Alloy internal electrodes reduce the production cost of MLCC products by more than 70%. At the same time, the miniaturization of the size and the high capacity of the empty value are progressing rapidly.

4. Advantages of MLCC development★ Miniaturization and thinning

Electronic products such as smartphones, computers, smart watches, and wearable devices are all moving towards miniaturization, and MLCCs in the upper reaches of the industry chain must be miniaturized to meet the needs of users. Ultra-small and ultra-thin capacitors will The realization of high-density installation of electronic equipment is conducive to the development of electronic equipment towards miniaturization.

★high frequency

The communication field is one of the main application scenarios of MLCC. From the perspective of communication, in order to improve communication quality and transmission capacity, it is an inevitable trend to explore higher frequency bands. From 2G to 5G, the frequency bands are getting higher and higher. The work of MLCC The frequency has also increased and has entered the millimeter wave frequency range.

★high temperature

At the same time, MLCC also needs to work in a high temperature working environment. The maximum working temperature of commonly used MLCC is 125°C. In order to meet the extreme working environment of special electronic equipment, the working temperature of MLCC is also gradually increased, reaching a maximum of 260°C.

★High Capacity

While pursuing miniaturization, MLCC also emphasizes higher capacity under the same size specification. As the functions of electronic terminals continue to increase and the battery capacity increases, it is necessary to configure large-capacity and high-quality MLCCs for stable and fast charging of large-capacity batteries. Some electronic circuits use large-capacity specifications to reduce the number of MLCCs, so there is a high requirement for large-capacity.

★High voltage resistance

Due to the high dielectric strength of the dielectric material used in MLCC, the working voltage ranges from several volts to tens of thousands of volts through flexible structural design. Driven by the trend of energy saving and emission reduction, the demand for related high-voltage capacitors will continue to grow. At the same time, MLCC continues to develop in terms of high-voltage resistance, forming a replacement trend for film capacitors, which also promotes the continuous growth of MLCC's high-voltage resistance demand.

★High safety and reliability

With the rise of markets such as electric vehicles, industrial equipment, and communications, more and more attention has been paid to the reliability requirements of MLCCs. Taking automotive MLCC as an example, its product development needs to meet the quality characteristics requirements of AEC-Q200 for passive components, and it also needs to improve the component strength, long-term operation, or humidity and temperature resistance.

5. Market size of MLCC industryMLCC is currently widely used in the fields of mobile phones, tablets, PCs, automobiles and consumer electronics. Mobile phones are the largest subdivision of its usage, reaching more than 35%, followed by consumer electronics such as audio and video, IOT, PC tablets and automobiles. Benefiting from the trend of vehicle electrification and intelligence and the rapid growth of 5G terminal shipments, the demand for the MLCC industry has accelerated, and the prosperity has continued to rise. According to relevant data, the global MLCC market size will be 101.7 billion yuan in 2020, and 114.8 billion yuan in 2021. It is estimated that by 2025, the global MLCC market size will reach 149 billion yuan, and the compound growth rate from 2020 to 2025 will be about was 7.9%.

Hangzhou Dahua Industry Control Technology Co., Ltd.

offer MLCC slitting machine