| Slitting Material | Film material such as flexible packaging film, BOPET, BOPP, BOPA, CPP,PE,metalizing film,coating film, lamination film, blowing film, calender film,paper and paper board, etc (Depend on request, quote based on customer material) |

| Material Thickness | 2.5um upwards (Depend on material) |

| Unwinding Width | Min 100um upwards (Depend on request) |

| Unwinding Diameter | 300mm-1500mm (Depends on request) |

| Rewinding Width | Same as mother roll |

| Rewinding Diameter | Same as mother roll |

| Winding Mode | Surface Center Winding/Center Winding (shaft type or station type) |

| Slitting System | Edge cutting or without edge cutting |

| Machine Speed m/min | 400m/min, 600m/min, 800m/min (Depend on requst) |

| Control System | SIEMENS Servo(Germany)/Inovance Servo (China) |

| Roller Surface | Cork tape/rubber/metal |

| Reverse function | Can be optional |

| Other auxiliary equipment | Can be optional |

| Remote Control Service | Include |

*The detail specifications depend on request.

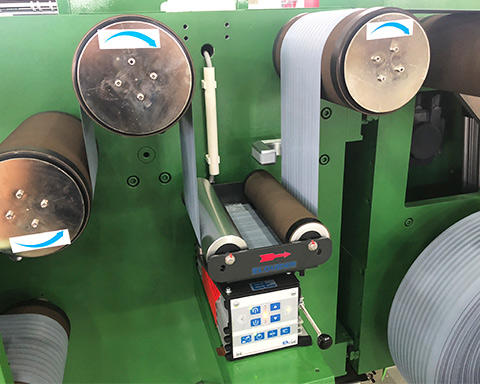

CCD Camera

Online edge guide

Splicing table

Based on the knowledge of processing material and machine mechanical electrical technology, Dahua concludes the machine design from traditional 1.0 to update 2,0 and 3,0 slitter, aiming to provide cost effective products with excellent advanced performance. The 4.0 machine is also ongoing and we believe it will bring brand new feeling. With the benefit of world sourcing and purchasing for machine components, Dahua sincerely hope to make your business competitive and could get back the investment shortly.

In order to provide professional solutions with quick production, the digital management system which integrates the ERP and MES function, working as the KBMS(knowledge base management system), not only deliver accurate proposals but also make the production on time.

The intelligent slitter consists of three experts to achieve one key solution. The processing expert grows from slitting and rewinding experience with different kind of materials. Transfer the 20+ years’ big data information into smart production. The operation expert knows what customer want, automatic function make the operation more easy and friendly. The maintenance expert is standby for 24 hours, remote control service eliminate the inconvenience of travelling especially at the epidemic time.

Intelligent slitting , reduce the dependence on users

Established in December of 1999, Hangzhou Dahua Industry Control Technology Co., Ltd. is a shareholder and national high-technology/software enterprise with multi-investment. Our focus is to specialize in high value-added R&D, sales, assembly, commission and service for slitting and rewinding industry.

As a leader of slitting and rewinding technology, we find a perfect solution for our everchanging customer requirements, and integrate this into our products design and manufacture, clarified the standard and positioning of slitter, and established version 1.0, version 2.0, version 3.0 and the concept of version 4.0, respectively. With the application of intelligent technologies, our products have been achieved high efficiency and high quality production with minimum dependence on operators. Currently our products have been very popular among the customers because of reliable R&D technologies, complete product series, superior quality and reasonable price, the products are exported to Germany, the United States, Japan and other developed countries, has become the preferred brand of the majority of customers.

After more than 20 years of precipitation and accumulation, our independently developed products and technologies have obtained 32 software copyrights, 42 utility model patents, 10 invention patents and 3 appearance patents

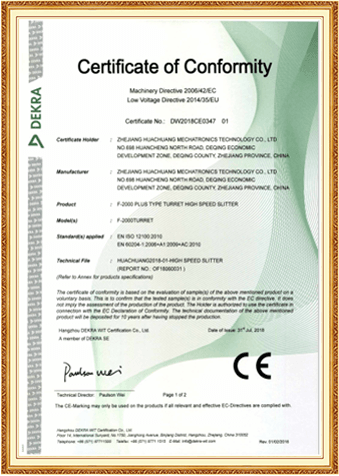

CE certification

CE certification

ISO9001 certification

ISO9001 certification

Alibaba certification

Alibaba certification

Provide you with the latest enterprise and industry news

Slitting machines, like many industrial machines, involve rotating parts, sharp edges, and high-speed operations that can pose significant safety risks to operators. To prevent accidents caused by pin...

READ MOREWhen selecting a paper slitter for high-speed, high-volume production, several key factors need to be considered to ensure efficiency, quality, and durability. These factors include: Slitting Speed an...

READ MORE1. Dimensional AccuracyTolerance Deviations: Vibration can cause inconsistent movement of the cutting tool or material during the slitting process, leading to deviations in the dimensional accuracy of...

READ MORESpeedCutting Speed: The cutting speed refers to how fast the blade or tool moves through the material. If the speed is too high, the blade may generate excessive heat, leading to potential material de...

READ MORECoil handling and material feeding systems are critical components of the Secondary Station Type Slitter and play an essential role in ensuring a smooth, efficient, and precise slitting process. These...

READ MOREThe speed of the shaft rotation plays a significant role in both the cutting accuracy and the production rate of a shaft-type slitting machine. Here's how it influences these two key factors: Impact o...

READ MOREThe role of Slitter Rewinder Machine

The role of a slitter rewinder machine is to accurately cut large rolls of material into narrower strips or rolls of a specific width and then rewind them onto smaller cores. This is a critical process in many manufacturing and production industries, such as paper, plastic, film, textiles, and metal processing, where materials are used in a variety of applications.

The slitter rewinder machine performs the following roles:

Unwinding: The machine unwinds the large roll of material and feeds it through the slitting section.

Slitting: The material passes through the slitting section where precision blades cut it into narrower strips or rolls of a specific width. The machine can be equipped with different types of blades for different materials.

Rewinding: The cut material is rewound onto smaller cores or shafts to create narrower rolls of the desired width. The machine can be equipped with different numbers of shafts to accommodate different rewinding requirements.

Inspection: The machine can be equipped with inspection systems to detect defects or inconsistencies in the material during the cutting process. This allows for quick identification and correction of issues, reducing material waste and improving quality control.

Control: The machine can be equipped with control systems to monitor and adjust various parameters, such as speed, tension, and cutting width, ensuring the production of high-quality and consistent finished products.

Overall, the slitter rewinder machine plays a crucial role in the production process of many industries, allowing for the efficient and accurate cutting of materials into narrower strips or rolls of a specific width, which can then be used for various applications. It improves production efficiency, reduces waste, and ensures high-quality finished products.

The production steps of Slitter Rewinder Machine

The production steps involved in manufacturing a slitter rewinder machine may vary depending on the specific design and requirements of the machine. However, here are the basic production steps that are involved in the manufacturing of a slitter rewinder machine:

Design: The first step is to design the slitter rewinder machine based on the specific requirements of the customer. This involves determining the machine's specifications, such as the maximum roll width, thickness, speed, and other key features.

Fabrication: The machine's frame, shafts, and other components are fabricated according to the design using specialized machinery such as lathes, milling machines, and welding equipment.

Assembly: The components are assembled to form the main body of the machine. This includes installing the slitting section, rewinding section, control systems, and other components.

Testing: Once the machine is assembled, it is tested to ensure that all components are functioning correctly, and the machine meets the customer's requirements. This involves running the machine with different materials and testing its performance under different conditions.

Inspection and Quality Control: After testing, the machine undergoes a detailed inspection and quality control process to ensure that it meets the required standards and specifications. Any defects or issues are identified and corrected.

Shipping and Delivery: Once the machine is approved for shipment, it is packaged and delivered to the customer's location. The machine may require disassembly and reassembly at the customer's site, depending on its size and complexity.

Overall, the production steps involved in manufacturing a slitter rewinder machine require specialized knowledge and equipment to produce a high-quality machine that meets the customer's requirements.