All the knowledge you want to know about multi-layer co-extruded barrier films is in it!1. What is a Multilayer Extrusion Film?Multilayer Extrusion Film refers to 3 or more layers of co-extrusion film containing barrier materials. This film is suitable for all flexible packaging fields, including food, daily chemical, beverage, medicine, electronic products, protective film, etc.

At present, the application rate of multi-layer co-extrusion technology has reached 76.9% in China, and it is expected to develop into more layer structures in the future, and expand from the packaging field to more other fields.

2. What are the advantages of Multilayer Extrusion Film?High barrier: Different plastic materials have different barrier properties, and Multilayer Extrusion Film can achieve high barrier effects on oxygen, water, carbon dioxide, and odor.

Strong functions: oil resistance, moisture resistance, high temperature cooking resistance of 120 degrees Celsius, low temperature freezing resistance, quality preservation, freshness preservation, and odor preservation.

Low cost: Due to the simple process, the film products produced by multi-layers can reduce the cost by 10-20% compared with other composite films.

Flexible structural design: Different structural designs can be used to meet different quality assurance requirements.

High strength: Multilayer Extrusion Film has the characteristics of stretching during processing, and the strength of plastic can be increased correspondingly after stretching, so that it has a composite strength exceeding ordinary plastic packaging.

No pollution: no residual solvent pollution problem, green and environmental protection.

3. How is the structure of the Multilayer Extrusion Film designed? The structure of Multilayer Extrusion Barrier Film includes symmetrical structure and asymmetric structure, wherein the symmetrical structure layer is composed of three types of functional layers: barrier layer, adhesive layer and support layer.

Barrier layer: The barrier layer adjusts the barrier properties of the film material through the control of the material and thickness of the barrier layer to meet different packaging needs. Commonly used barrier materials in the market include PA, EVOH, PVDC, etc. The barrier layer has the functions of oxygen barrier, moisture barrier, Prevent oil leakage and other functions.

Support layer: Generally, symmetrical structure materials have two support layers, the inner layer is used for heat sealing, and the outer layer is directly used as the outer layer of the packaging film or used for printing to become the printing layer. The support layer needs to have good mechanical strength, heat sealing performance, water vapor resistance, transparency and printability. The commonly used material for this layer is LDPE or a combination of LDPE and LLDPE.

Adhesive layer: The function of the adhesive layer is to bond the barrier layer and the support layer to ensure the peeling force between the layers. The selection of the material and thickness of the adhesive layer is generally based on the material of the support layer and the barrier layer and the bond strength to be achieved To determine the adhesive material used for the adhesive layer.

4. Which materials can be used for Multilayer Extrusion Laminated Film? Multilayer Extrusion Laminated Film is mostly composed of polyolefins. Currently, the most widely used structures are: PE/PE, PE/EVA/PP, LDPE/adhesive layer/EVOH/adhesive layer/ LDPE, LDPE/adhesive layer/EVOH/EVOH/EVOH/adhesive layer/LDPE.

The thickness of each layer can be adjusted through the extrusion process. By adjusting the thickness of the barrier layer and the combination of various barrier materials, films with different barrier properties can be flexibly designed, and the materials of the heat-sealing layer can be flexibly replaced to meet the needs of different packaging. The multi-layer and multi-functionalization of this co-extrusion composite is the mainstream direction of the development of packaging film materials in the future.

5. Multilayer Extrusion Barrier Film process selection★Casting Extrusion Barrier Film

The process is a multi-layer co-extrusion barrier film produced by casting method. The tape casting method is currently the method with the largest output in the mature process of producing multi-layer co-extruded barrier films. Usually, the daily production capacity of the tape casting equipment with a width of 1.6 m can reach about 20 tons.

Casting co-extruded barrier film has high transparency and very uniform film thickness, usually the deviation can be controlled at about 3%, which is suitable for food packaging with high requirements.

★Upblowing Extrusion Barrier Film

This process is a multi-layer co-extrusion barrier film produced by the up-blowing process. The production capacity of multi-layer co-extrusion barrier film produced by the upward blowing method is the lowest. Usually, the daily production capacity of the upward blowing production line with a width of 1.6 m is less than 5 tons.

The up-blowing method is easy to operate and requires less investment in equipment. It is the most common process for producing multi-layer co-extruded barrier films. In addition, due to the lower output, the upward blowing method has more flexible advantages in the processing of some special small quantities of packaging materials.

★Water-cooled Blowing Extrusion Barrier Film

This process is a multi-layer co-extrusion barrier film produced by down blowing process and water cooling. The production capacity of multi-layer co-extruded barrier film produced by water-cooled down-blowing method is moderate, and the daily production capacity of a down-blown water-cooled production line with a width of 1.6m is nearly 8 tons.

The multi-layer co-extruded barrier film is produced by the down-blowing method, and the melt can be crystallized quickly by cooling water, which makes the film have very high transparency and a large stretching rate, so it is very popular in the field of meat food packaging. However, due to special reasons such as the film needs to overcome the influence of downward gravity in the casting down blowing water cooling method, the thickness uniformity of the film product is poor, usually about 5%.

★Biaxially Oriented Extrusion Barrier Film

The process is a multi-layer co-extrusion barrier film produced by biaxial stretching co-extrusion method. This kind of process is currently rarely used in the world, and only a few factories in the world can produce biaxially stretched co-extruded barrier film production lines.

The production capacity of this process is large, and the thickness of the barrier film produced is very uniform and the transparency is excellent. In addition, the tensile strength of this film of the same thickness is much higher than that of the films produced by the other three processes, and the performance is excellent. Of course, the investment of this kind of process production line is not cheap, usually the investment of a line is more than 100 million yuan.

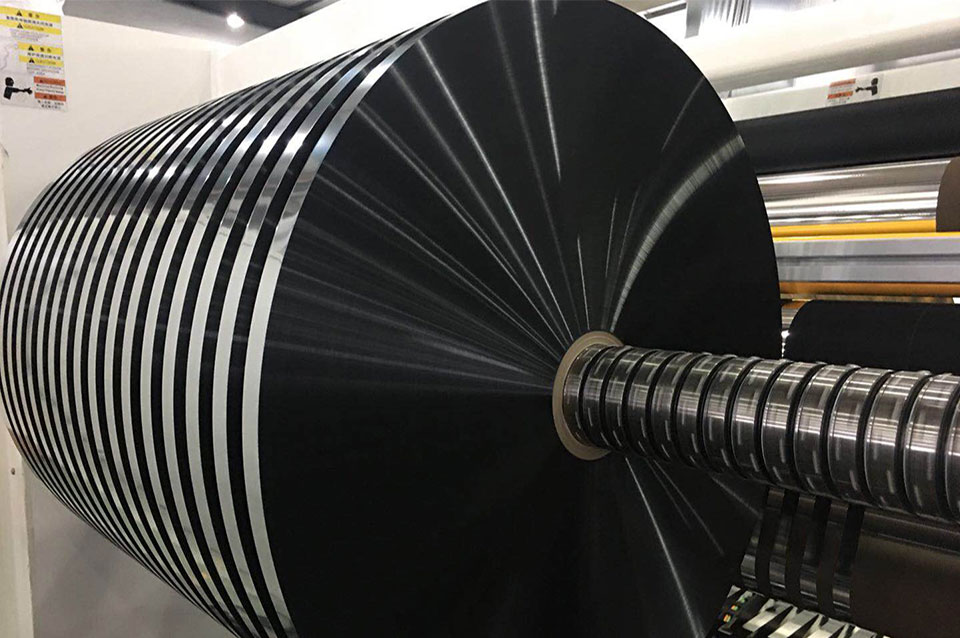

Hangzhou Dahua Industry Control Technology Co., Ltd. offe

r Multilayer Extrusion Film Slitting Machine and

Multilayer Extrusion Barrier Film Slitter