Intelligent slitter, reduce the dependence on users

To be the most popular supplier in the world for slitting and rewinding solutions

Based on the experience more than 20 years

Minimum tension

Minimum material thickness

Narrowest rewinding

Web width up to

Max running speed

Machine Running In The World

Machine Types Provided To Customer

1.BOPP, BOPET, CPP, BOPA, PE, PET-G,etc

2.Metallized film

3.PVDC, silicon coating, Alox coating

4.High barrier multilayer extrusion film

5.Shrink film/Stretch film

6.Printing laminating film

7.PVC soft/rigid film

8.Holographic film

9.Thermal lamination film

10. Tobacco packaging film

11....

1. PET Optical Grade Film

2. PET Window Film

3. BOPET/BOPP Capacitor Film

4.LCD film

5.OCA Film

6.TAC film

7.BOPI film

8. Protective Film

9. Aluminum Plastic Lamination Film

10....

1.Lithium Battery Separator Film

2.PE Polyethylene Battery Separator Film

3.Solar Energy Backboard

4.PVDF Film

5.EVA Film

6.PET copper coating

7....

1.Laminate Paper For Aseptic Packaging

2.Bobbin Core Paper

3.Metalize Paper/Transparent paper

4.Pressure Sensitive Paper, Thermal Sensitive Paper

5.Silicon Coating Paper

6.Adhesive Label Products

7.Industry Adhesive Tape

8.Insulation paper

9.Glass Fiber Paper

10....

1.Breathable PE film

2.Medical filter paper

3.Medical infusion material

4.PVC blister film

5.Tevak

6....

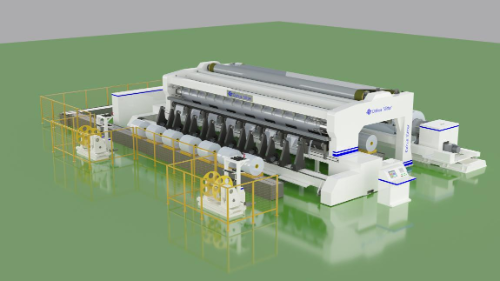

Provide professional solutions from 1.0 generation to 4.0 generation

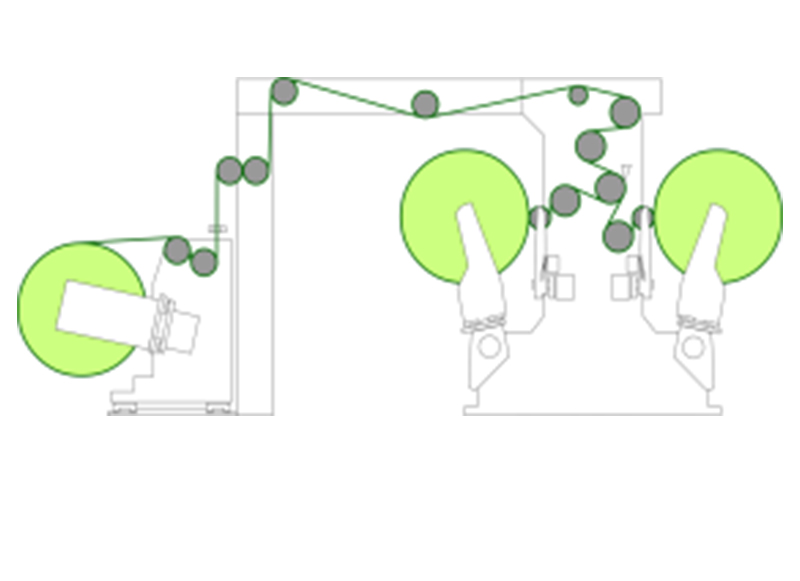

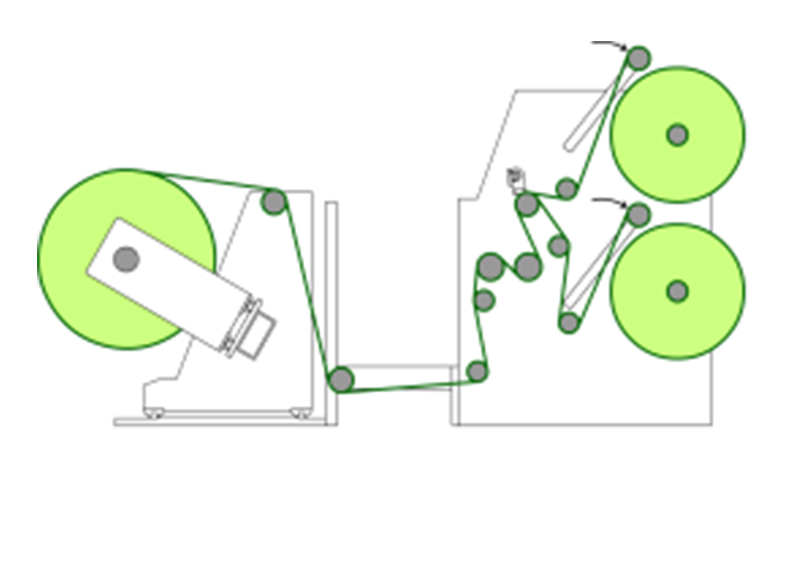

Regular design more than 20 years ago.

1.Separate unwnding and rewinding part, easy for installation.

2.Flexible roller position to make the material more flat during running.

3.Solid machine frame for stable running.

4.Cost effective design with reliable slitting performance.

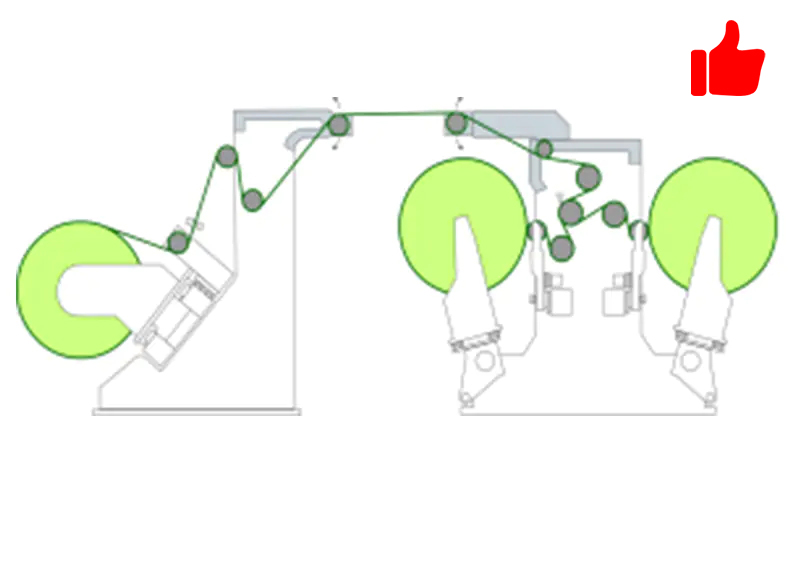

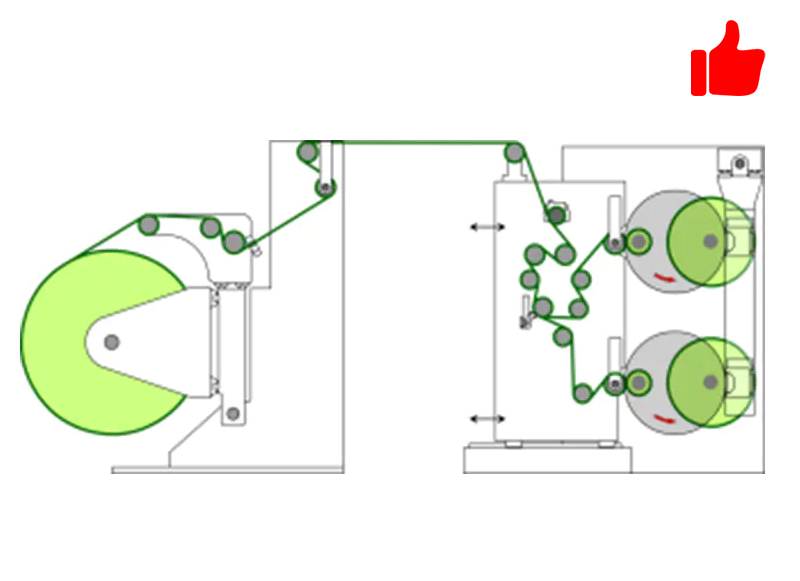

1.Suitable for high tech material slitting.First choice of top customers.

2.Intelligence and automation,improve accuracy and efficiency.

3.Good appearance, new visual feeling.

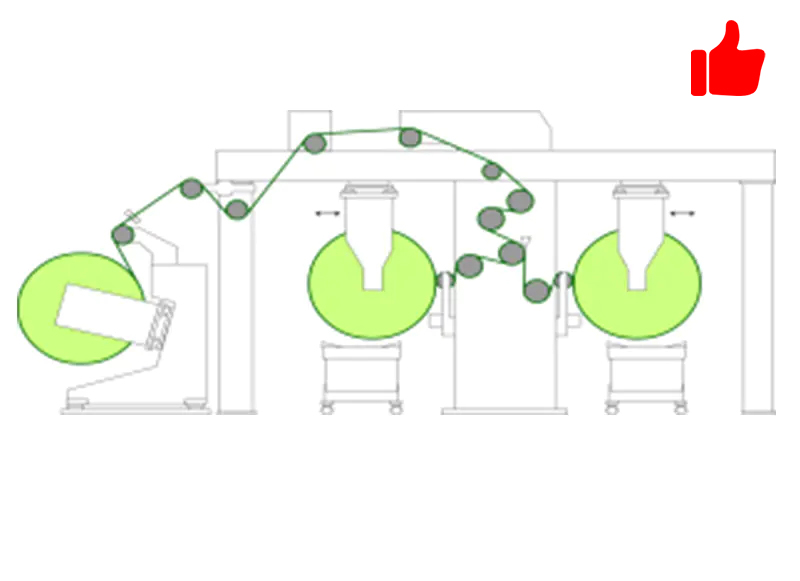

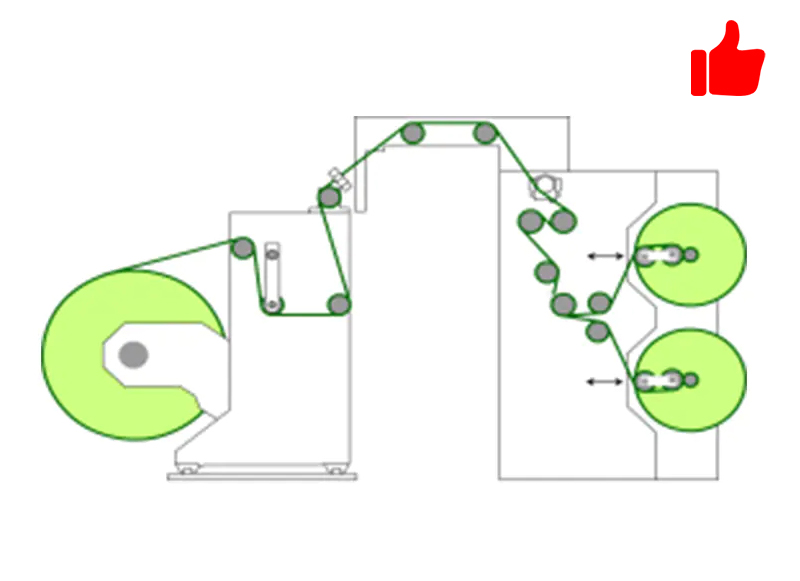

Regular design more than 20 years ago.

1.World advanced technology with reasonable price.

2.Automatic function can be intergrated.

1.Suitable for high tech material slitting.Design for high level.

2.World advanced technology with reasonable price.

3.Intelligency and automation, improve accuracy and efficiency.

4.Good appearance, new visual feeling.

Provide you with the latest enterprise and industry news

The global plastics industry event, PLASTINDIA 2026, is just around the corner! ...

READ MOREThe premier global event for the plastics and rubber industry—K 2025 in Germany—...

READ MORE

Slitting machines, like many industrial machines, involve rotating parts, sharp ...

READ MORE

When selecting a paper slitter for high-speed, high-volume production, several k...

READ MORE

1. Dimensional AccuracyTolerance Deviations: Vibration can cause inconsistent mo...

READ MORE

SpeedCutting Speed: The cutting speed refers to how fast the blade or tool moves...

READ MORE

Coil handling and material feeding systems are critical components of the Second...

READ MORE

The speed of the shaft rotation plays a significant role in both the cutting acc...

READ MORE

Implement Advanced Tension Control SystemsWhy It Matters: Maintaining consistent...

READ MORE

Maintain Proper Blade ConditionProblem: Dull, worn, or damaged blades can lead t...

READ MORE

To ensure the optimal performance and longevity of a shaft-type slitter, regular...

READ MORE

The use of rotating shafts in a shaft-type slitter is fundamental to the precisi...

READ MORE