What is aluminum-plastic composite film?

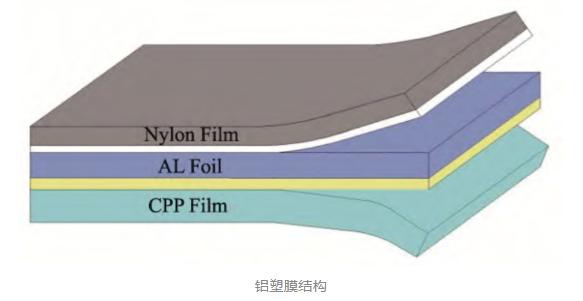

Aluminum-plastic composite film (Aluminum-plastic composite film) is a packaging material for pouch batteries. It is a high-strength, high-barrier multilayer composite structure composed of various plastics, aluminum foil and adhesives. Aluminum-plastic composite film flexible packaging can be divided into three layers: the outer nylon layer, the middle aluminum foil layer and the inner polypropylene film layer, and the layers are bonded by adhesives.

Aluminum-plastic composite film internal structure

External nylon layer (ON layer): The external ON layer protects the AL layer from scratches, and the outer layer material is required to have good heat resistance, abrasion resistance, puncture resistance and bending resistance, etc., considering the outer layer material Due to the cost problem, polyester and nylon non-ferrous metal processing film materials are usually selected.

Middle aluminum foil layer (AL layer): The AL layer acts as a barrier to prevent moisture intrusion and block oxygen to protect the contents of the battery.

Inner heat-sealing layer (CPP layer or PP layer): The inner layer is an electrolyte-resistant layer to prevent the leaked electrolyte from corroding the AL layer, and requires high composite strength with the aluminum foil layer. Film materials such as polypropylene, polyethylene, ethylene acrylic acid copolymer, polypropylene or ionomer resin are more commonly used.

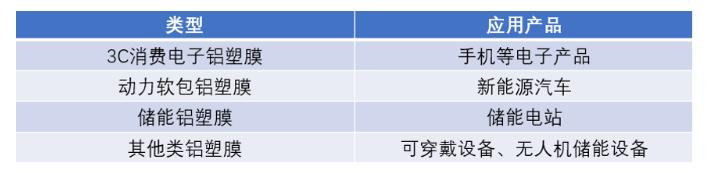

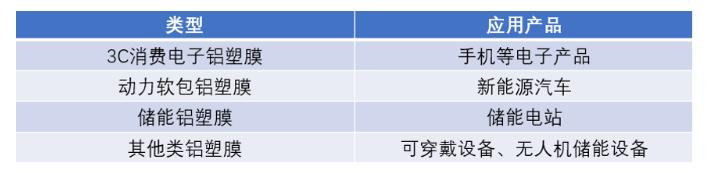

Application of aluminum-plastic composite film

Due to the advantages of light weight, thin layer and flexible design, aluminum-plastic composite film has been widely used in many fields such as 3C consumer electronics, power batteries, and energy storage. It mainly plays the role of protecting internal electrodes and isolating the external environment.

Process selection of aluminum-plastic composite film

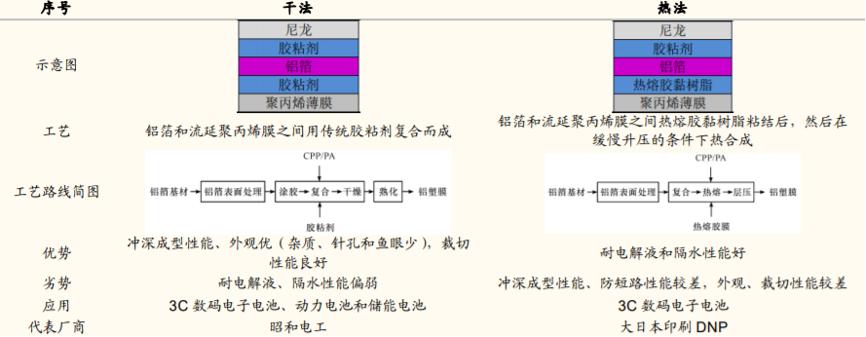

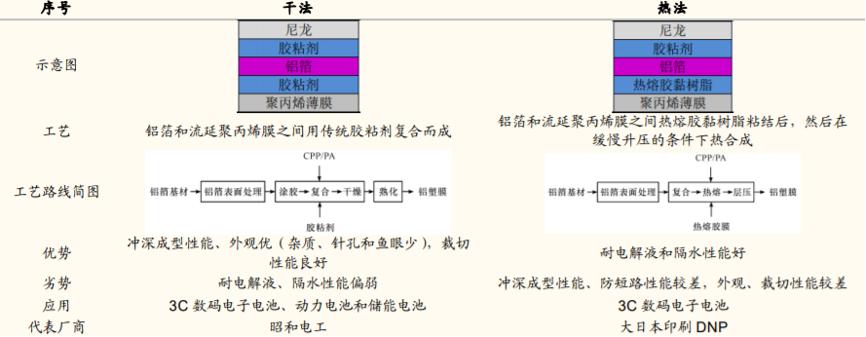

Glue is mainly used for bonding between the outer nylon layer and the middle aluminum foil layer, and the bonding methods between the middle aluminum foil layer and the inner heat-sealing layer are mainly divided into dry method and thermal method.

The dry process is to bond the middle aluminum foil layer and the inner heat-sealing layer with an adhesive, and then synthesize them under dry pressing. The advantages are good drawing and forming effect, good appearance consistency, less prone to pinholes, fish eyes, impurities and other defects, but its resistance to electrolyte is poor.

The thermal process is that the middle aluminum foil layer and the inner heat-sealing layer are bonded with MPP, and the temperature is raised slowly and the pressure is heat-pressed. The thermal process can improve the adhesion between the middle aluminum foil layer and the inner heat-sealing layer, and the electrolyte resistance is improved. The disadvantage is that this special treatment of MPP needs a higher temperature to melt it to achieve bonding. After cooling, due to the large difference in shrinkage coefficient with PP, it is easy to curl inward.

At present, the dry process is the production process generally adopted by mainstream aluminum-plastic film manufacturers in the market.

Market size of aluminum-plastic composite film

According to relevant data, under the general trend of new energy, the demand for aluminum-plastic film for global soft-pack power batteries is accelerating. Relying on the growth of the industry and the improvement of penetration rate, power batteries will gradually become the core driving force driving the growth of demand for aluminum-plastic film. It is estimated that the global demand for aluminum-plastic film will increase to 780 million square meters in 2025, and the market space will exceed 10 billion.

If you are looking for cutting machines for aluminum-plastic composite film materials, Hangzhou Dahua Industry Control Technology Co., Ltd. provides you with high-quality

slitter machines, which are efficient, fast and wrinkle-free, and are your best choice.