1. The concept of capacitive film

Capacitor film refers to a type of film used in film capacitors. Common plastic films such as polyethylene, polypropylene, polystyrene or polycarbonate.

Capacitor film and electrodes such as metal foil are stacked from both ends, and the structure wound into a cylindrical shape is called a capacitor.

At present, a thin layer of metal is directly vacuum-evaporated on the plastic film as an electrode, so as to save the thickness of the electrode foil, reduce the volume of the capacitor unit capacity, and make the capacitor with large capacity. Such films, represented by metal BOPP films, have become the mainstream products of capacitor films.

2. BOPP capacitive film industry

The domestic production of capacitive film for capacitors started in the early 1980s and late 1980s.

As Jiangmen Xinhui Capacitor Film Factory (now "Jiangmen Runtian Industrial Investment Co., Ltd.") took the lead in introducing film production lines, a competitive pattern of "four factories and five lines" was formed in China, with an overall production capacity of 6,000 tons per year. Product specifications are basically based on a thickness of 8 μm or more, and ultra-thin films and high-end products mainly rely on imports.

In the 1990s, with the rapid development of the domestic information industry, household appliances, and consumer electronics industries, as well as the country’s continuous increase in investment in power infrastructure, the film capacitor industry began to show explosive growth, which triggered the domestic capacitor film industry. The second investment boom.

After more than 20 years of development, the domestic capacitor film industry has now formed a competitive landscape of 12 companies with more than 30 production lines. Product quality and technology research and development capabilities have been greatly improved, and the minimum product thickness has reached 2.8μm.

At present, domestic enterprises have reached or surpassed foreign enterprises in terms of product quality and technical level, and have begun to export batches of products abroad while meeting the domestic high-end market's demand for technical quality.

3. Production process of BOPP capacitor film

At present, the production process of capacitor film mainly adopts the flat film method: the melt of high molecular polypropylene is made into a sheet or thick film through a narrow and long die, and then in a special stretching machine, at a certain temperature and a set speed Next, stretching in two vertical directions (longitudinal and transverse) at the same time or step by step, so that the crystallizable surface of the molecular chain of the polymer is oriented in a direction parallel to the plane of the film and arranged in an orderly manner; then in Heat setting under tension to fix the oriented macromolecular structure, and it is made by proper cooling or heat treatment or special processing (such as corona, coating, etc.).

The method can produce wide-width film at high speed, and the product has uniform thickness and stable performance.

The flat die method is the most advanced production technology in the world today, featuring high efficiency and automation, but a complete set of key production equipment still needs to be imported.

4. BOPP capacitive film market

The downstream of BOPP capacitor film is relatively simple, and it is basically used to produce film capacitors.

The main raw materials of film capacitors are capacitor films, metal materials, resin materials, lead wires and tab materials, and shell materials, among which capacitor films account for about 70% of the total cost of all raw materials.

Therefore, the industry situation and market capacity of film capacitors directly determine the development of the capacitor film industry.

Since the 1990s, the global thin film industry for capacitors has maintained an annual growth rate of 10-20%.

From the perspective of our country, the film industry for capacitors started relatively late, but it has developed extremely rapidly. In 2007, the total industrial output value of my country's capacitor and supporting equipment manufacturing industry was 16.394 billion yuan, and the sales revenue was 15.468 billion yuan; in 2012, it increased to 36.642 billion yuan respectively. RMB 35.842 billion, an increase of 123.5% and 131.7% over 2007 respectively.

In the future, with the further development of digitization, informatization and network construction and the country's increased investment in power grid construction, electrified railway construction, energy-saving lighting, hybrid vehicles, etc., as well as the upgrading of consumer electronics products, it is expected that my country's thin film electronics will The container market will grow steadily at a rate of around 10%.

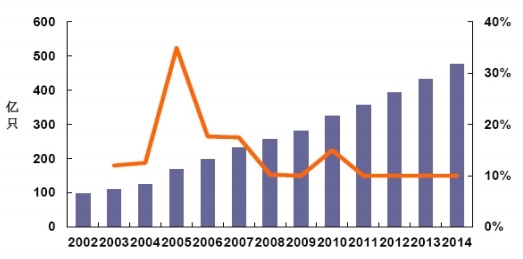

Total output of film capacitors in my country

Judging from the current demand, the following six major industries will provide support for the BOPP capacitor market.

★Consumer Electronics

★Hybrid car market

★Grid construction market

★The demand for new energy capacitors is strong

★Promotion of green lighting

★Rapid development of railway electrification

5. Raw material of BOPP capacitive film

Polypropylene is mainly polymerized from propylene monomer, referred to as "PP", and its density is 0.9g/cm3. It is one of the lightest resin varieties. It has high transparency, light specific gravity, easy processing, high strength, acid and alkali resistance, Good electrical insulation and other excellent properties.

Domestic polypropylene resin currently mainly relies on foreign imports, and the main suppliers are Borealis, Korea Petrochemical, Sumitomo Asia, and Japan's Mitsubishi.

Other raw materials include aluminum wire, zinc strips and packaging, etc. The proportion of such raw materials is relatively low and the supply is sufficient.

6. Development trend of BOPP capacitive film

★The application fields of polypropylene film capacitors are expanding

With the continuous development of science and technology, the application fields of film capacitors are also expanding.

In addition to traditional AC motors, AC motor capacitors for consumer electronics and household appliances, air conditioner and refrigerator compressor capacitors, and various power capacitors, other capacitors such as electric locomotive capacitors and hybrid electric vehicle capacitors have developed. The fields of application of thin films are also expanding.

★From the general trend, the thickness of the film is developing towards thinner

Due to the continuous improvement of the quality of capacitor films, the performance of BOPP has been greatly improved, especially the uniformity of thickness, electrical properties and other indicators have been greatly improved. The voltage withstand of the film has been significantly improved.

The capacitance of the capacitor is C∝S/d (S is the area of the capacitor film, d is the thickness of the film). Therefore, under the premise that the reliability of the film is guaranteed, the capacitor manufacturer must reduce the cost and volume of the capacitor during the manufacturing and storage process. For film capacitors with the same electrical energy, the cost advantage of manufacturing thin film with smaller thickness specifications is obvious and its volume is smaller.

★Demand for high temperature resistant capacitor films will show an upward trend

Due to the demand of manufacturers for large capacity and the use of products is becoming wider and wider, such as power capacitors, electrical equipment capacitors, electric locomotive capacitors, hybrid electric vehicle capacitors, automotive electronic capacitors, HID lamp capacitors, etc.

Nowadays, the requirements for the reliability of capacitor films are getting higher and higher, especially for the temperature resistance of capacitor films, so as to meet the high temperature rise of large-capacity capacitors during use, poor environmental heat dissipation conditions and high ambient temperature, etc. The requirement that the performance is not affected under harsh conditions.

The temperature resistance of high temperature resistant capacitor film is much better than that of ordinary capacitor film. The capacitor produced by it has high reliability and can work for a long time in a harsh environment. Therefore, BOPP high temperature resistant capacitor film will be a development direction.

★Development of new high dielectric constant capacitor film

The dielectric constant of polypropylene material is not very high, which is an inherent characteristic of polypropylene. Therefore, the volume of capacitors manufactured using capacitive films is relatively large.

In order to achieve the purpose of constant capacity and other electrical properties without changing the volume, it is an effective direction to develop a high dielectric constant capacitor film. Technologies such as nanotechnology, cross-linking, grafting technology, and silicon oxide plating have made this This idea is a big step towards possibility.

Once this idea is implemented, the miniaturization of polypropylene film capacitors will become possible, and it also means that the unit capacitance cost will be greatly reduced, and the product gross profit rate will be greatly improved.

Hangzhou Dahua Industrial Control Technology Co., Ltd. is a leading manufacturer of slitter rewinders in China. Our company is located in Hangzhou, covering an area of 30,000 square meters. It is a leader in

BOPP capacitor film slitting machine rewinding technology.

Duahua as a professional China slitting machine manufacturer and slitter machinery factory, we offer wholesale high-precision configuration

BOPP capacitior film slitter for sale online.