Solar cell backsheet, also known as photovoltaic backsheet, solar backsheet, solar cell backsheet film, photovoltaic backsheet film, is widely used in solar cell (photovoltaic) components. It is located on the back of the solar panel. It can not only protect the Solar cell modules are not corroded by water vapor, and can block oxygen to prevent internal oxidation of the module. They have reliable insulation, water resistance, aging resistance, high and low temperature resistance, and corrosion resistance. In addition, the solar cell backsheet can reflect sunlight, improve module conversion efficiency, and has high infrared reflectivity, which can reduce module temperature.

2. The structure of the solar cell backplane

The structure of solar cell backsheet is generally divided into five layers, including three core layers: outer protective layer (weather-resistant layer), middle layer and laminated adhesive layer.

Outer protective layer (weather-resistant layer): In order to obtain good weather resistance, the outer layer material is generally required to contain fluorine. PVF and PVDF are two well-known weather-resistant polymer materials.

Middle layer: plays a supporting role, should be able to withstand high and low temperatures, have stable mechanical properties, excellent electrical insulation, good creep resistance, fatigue resistance, friction resistance and dimensional stability, and have low air permeability, gases and steam. . Generally, modified PET material is used.

Laminated adhesive layer: The bonding strength of unmodified fluorine-containing film and PET to EVA is poor, so it is necessary to use modified fluorine-containing materials or EVA, PE, and PA films with stronger adhesion.

If you need to cut the solar cell backsheet, you must ensure the compatibility of the machine when using

film slitter. The blades of the

Slitters must be sufficiently sharp, and appropriate tension control and anti-static measures can ensure that the performance of the solar cell backsheet is not damaged during cutting.

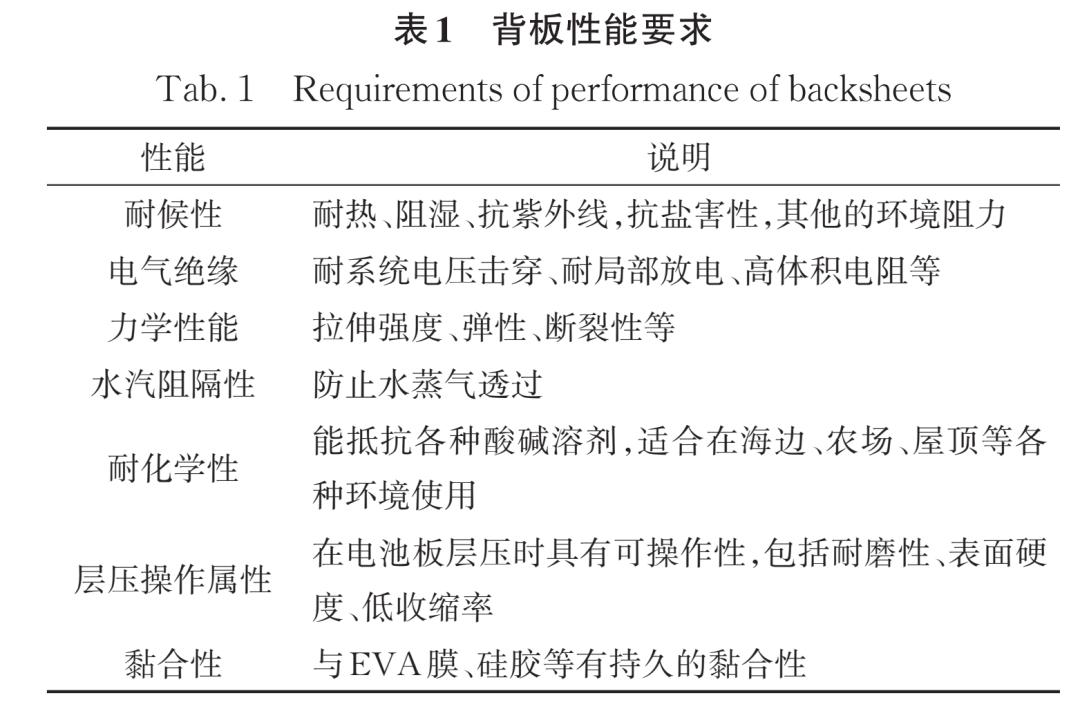

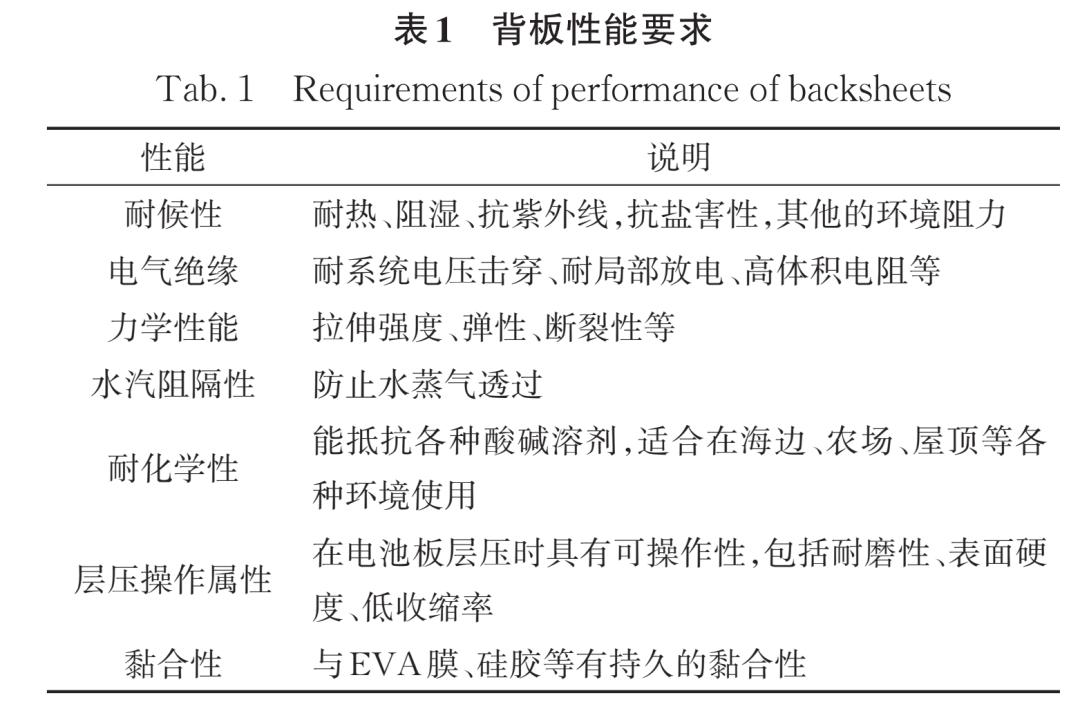

3. Performance requirements of solar cell backsheet

Solar cell backsheets have strict requirements in terms of weather resistance, electrical insulation, mechanical properties, water vapor barrier properties, chemical resistance, lamination operation properties and adhesion. Please refer to the figure below for details.

4. Classification of solar cell backsheets

According to the classification of backsheet film, it can be divided into three types:

Glue-coated composite backsheet film: fluorine composite film or EVA film, PET polyester film on both sides, three-layer structure.

Coated backsheet film: Coat fluorinated resin on both sides of PET polyester film, dry and solidify to form a film.

Some manufacturers also use cross-linking reaction methods to react with cross-linking agents on both sides of PET to produce composite films or EVA films.

5. Development trends of solar cell backsheets

The intrinsic driving force driving the photovoltaic backsheet industry is mainly performance and cost.

From a performance perspective, the backsheets of high-demand components basically use fluorine-containing materials to protect PET. The only difference is the fluorine materials used. Whether the fluorine material is in the form of a film or directly coated on PET with paint are the two main directions for the development of PET backsheets.

From a cost perspective, the cost of film coating is much lower than that of film coating. As the profit margin of photovoltaic products continues to decline, the development of film-coated backsheet products is the only way for photovoltaic backsheets. However, the adhesion and stability of the coated backsheet still need to be continuously improved.

The ultimate trend for backsheets should be to find a material with better weather resistance to replace PET backsheets.