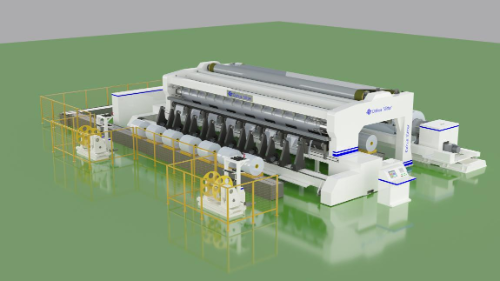

Let's explore how the structure of the

Primary Slitter framework contributes to the steadiness of the device in element:

Material Selection:

The preference of substances for constructing the framework performs a important function in enhancing balance. High-quality substances with suitable properties, inclusive of metallic or other alloys, are frequently decided on. These substances provide robustness and sturdiness to withstand the dynamic forces and vibrations related to slitting operations.

Rigidity and Stiffness:

The framework is designed to show off high pressure and stiffness. This is executed thru considerate engineering and material selection to limit flexing or bending for the duration of operation. A rigid framework ensures that the slitter continues its structural integrity, particularly when subjected to various hundreds and forces.

Welding and Joining Techniques:

The welding and joining strategies used in constructing the framework are essential factors. High-first-rate welding practices make a contribution to the seamless integration of additives, lowering the chance of vulnerable factors or stress concentrations. Precision in welding complements the overall stiffness of the shape.

Reinforcements in Critical Areas:

Critical regions of the framework, which include those helping heavy additives or experiencing high stress, can also have additional reinforcements. These reinforcements, strategically positioned, distribute loads extra effectively, reducing the threat of deformation or fatigue in particular regions of the structure.

Vibration Damping Solutions:

Incorporating vibration damping answers within the framework is essential. This could contain the use of dampening materials, isolators, or structural functions designed to take in and dissipate vibrations generated throughout the slitting method. Effective vibration manage contributes to universal stability and precision in slicing.

Modular Design Principles:

A modular design technique is regularly followed, taking into consideration the development of the framework in awesome, interlocking sections. Modular designs decorate stability with the aid of minimizing the impact of localized stresses and facilitating easier protection or replacement of precise components with out compromising the general shape.

Finite Element Analysis (FEA):

Finite Element Analysis is regularly hired at some stage in the design phase. This simulation method facilitates engineers examine the structural integrity of the framework underneath unique masses and conditions. By optimizing the design primarily based on FEA results, the stableness of the slitter can be drastically stepped forward.

Adjustable Leveling Systems:

The framework may feature adjustable leveling systems. These systems allow operators to first-class-music the leveling of the slitter at the manufacturing ground. Ensuring that the machine is level contributes to balance and steady performance.

In summary, the shape of the Primary Slitter framework improves stability via a aggregate of fabric selection, pressure, reinforcements, vibration damping, modular design, finite element evaluation, foundation considerations, adjustable leveling systems, and cautious consideration of dynamic load distribution. These factors together create a robust and solid framework this is crucial for the precision and reliability of the slitting technique.