Yes, the Secondary Slitter is often designed to handle specialty materials with unique properties, including adhesive-backed films or films with special coatings. Here's an explanation:

Adhesive-Backed Films:

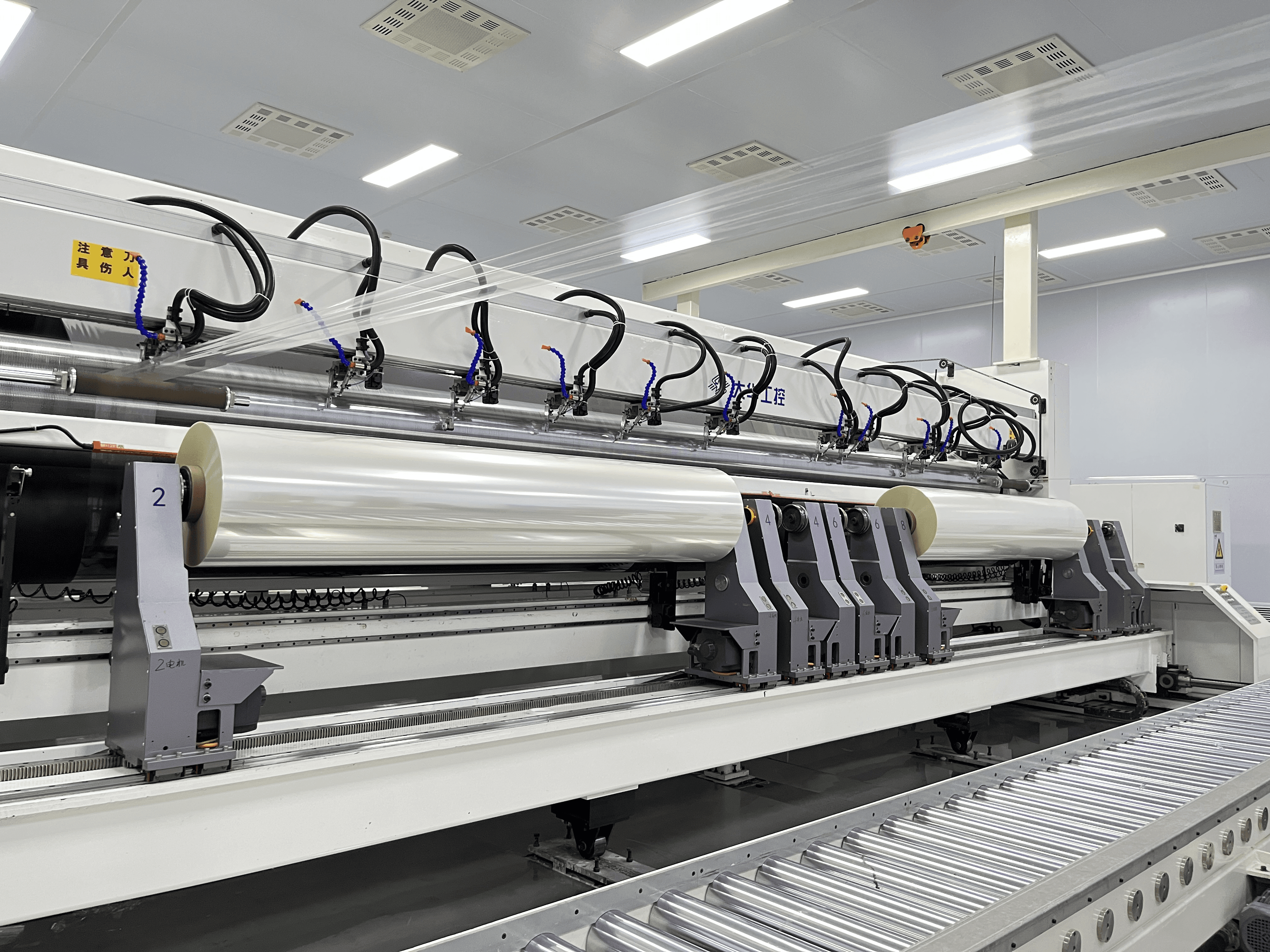

The Secondary Slitter is equipped to handle adhesive-backed films by incorporating features that prevent adhesive buildup on the slitting blades. Special coatings on the blades or non-stick surfaces help minimize adhesion, ensuring clean cuts without compromising the adhesive properties of the film. Additionally, the machine may include systems for managing adhesive waste and preventing contamination of the slitting mechanism.

Films with Special Coatings:

Films with special coatings, such as anti-static coatings, release coatings, or protective coatings, can also be processed by the Secondary Slitter. The machine is designed to accommodate these coatings without causing damage or compromising their functionality. Adjustments in blade materials or configurations may be made to ensure compatibility with specific coatings, and the machine may incorporate features for precise edge trimming to maintain the integrity of the coating along the slit edges.

Precision Handling:

The Secondary Slitter employs precision handling mechanisms to ensure accurate slitting of specialty materials with unique properties. This includes precise tension control, adjustable slitting parameters, and sophisticated guidance systems to maintain material alignment during the slitting process. These features contribute to the machine's ability to handle a wide range of specialty materials while maintaining high-quality slitting results.

Customization Options:

Manufacturers may offer customization options for the Secondary Slitter to meet specific requirements of handling specialty materials. This can include adjustable settings, specialized blade configurations, or additional modules tailored to the unique properties of the materials being processed. By offering customization options, the machine can effectively handle various specialty materials with diverse properties and characteristics.